About ConeCraft

Where bioprocessing meets value engineering

Founded in 2003 to deliver engineered solutions to the growing single-use technologies biopharma market, ConeCraft has been at the vanguard of biopharmaceutical engineering both Stainless Steel and Single Use Technology ever since.

At ConeCraft, we strive to design equipment that improves your bioprocess through reliable functionality, ease of operation, flexibility, safety and workflow. With demonstrated capabilities and agility, we specialize in design engineering, fabricating and testing equipment for use in cGMP environments. ConeCraft holds patents to key features that enhance SUT systems making them safer, more reliable and easier to operate.

Leveraging decades of project execution experience, risk mitigation is our primary focus to deliver maximum possible security for your high value products. All equipment provided by ConeCraft is available for Factory Acceptance Testing at our facility in Fort Worth, Texas.

We ship domestically and globally and provide all support and spare parts for successful installation and throughout equipment life cycle.

Our Values

-

ConeCraft is a full-service engineering house focused on single-use technologies (SUT) biomanufacturing modalities and their applications.

SUT equipment designed by ConeCraft LLC can be found in GMP operations at numerous Biopharma companies around the world.

ConeCraft offers a standard design with options for additional functionality such as ASME-Stamped jacket, temperature control, smart hoist for BPC lift, circulation, level measurement, weight measurement, probes and transmitters, filter and tubing management systems.

Configuration options such as portability, stackability, UV protection and seismic anchorage.

ConeCraft equipment is made for critical aspects of Single Use Bioprocessing.

-

Holistic Approach, more critical to get the right solution at the lowest risk.

Scope of supply is based upon ConeCraft’s detailed design approach and your process requirements. We define full scope of work and project drivers to minimize Change Orders.

Patented equipment features and quality driven fabrication differentiate ConeCraft equipment solutions.

All ConeCraft SUT equipment can be modified to accommodate space constraints while targeting required volumes.

ConeCraft focus on project functions and areas of risk mitigation through our approach include but are not limited to resources for design, build and installation, full system testing and signoff during FAT, and engineering support for installation activities. These are included in the ConeCraft Single Use Technologies solution and are gaps to successful project execution we fill and take responsibility for.

ConeCraft is where SUT bioprocess meets flexible value engineering.

-

ConeCraft designs and manufactures equipment for AAV, CGT, mRNA, Vaccines, mAb, and Recombinant Proteins/Hormones Biomanufacturing.

Flexible Portable or Stationary equipment for Media, Buffer, and Additions Management Upstream or Downstream.

Ideal for R&D, Pilot, and Commercial scale; Suite or Ball Room layout.

BPCPs are Universal: ConeCraft BPCPs, Bio Process Container Platforms use 3D BPCs (“bags”) from numerous GMP Validated BPC Manufacturers around the world increasing your supply chain security.

Low-risk patented BPC loading process increases supply chain security by lowering damage while loading.

ConeCraft capability includes our UL Certified Panel Shop on site which allows us to control critical long-lead components for bolstered supply chain security and best schedule.

Custom engineering to address process needs, facility spatial constraints and operational preferences.

-

At ConeCraft we build Mutually Beneficial Partnerships where all parties win and have a net benefit.

For us trust and respect are key, and we are intentional and authentic in our quest for those ideals.

ConeCraft project execution is a holistic approach that has been developed over decades and considers all impacts to your project and mitigates those impacts.

ConeCraft project execution is a holistic approach, and we succeed together through partnership.

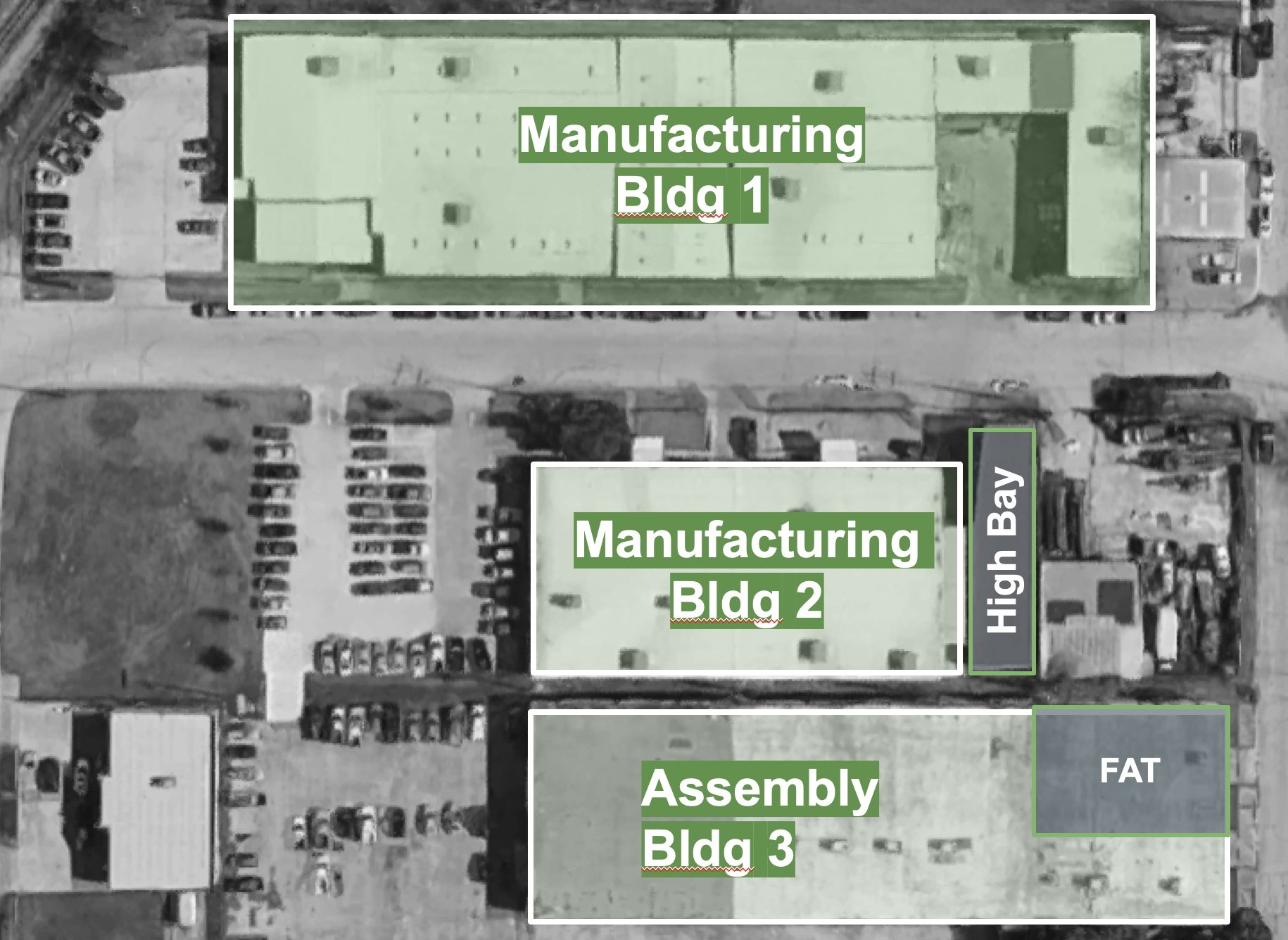

High Bays for large vessel assembly

Fiber Laser Cutter

110,000 ft2 of production capacity

Additional capacity added in 2022

50+ welding bays

Dedicated FAT area with 3 conference rooms

UL Certified Panel shop

ASME pressure vessel (U, R Stamp)

Meet the Team

-

Jim Austin

FOUNDER & CEO

-

Dominic Orlando

DIRECTOR OF BUSINESS DEVELOPMENT

-

Weldon Weeks

CHIEF OPERATING OFFICER